APOCALYPSE DIESEL PERFORMANCE

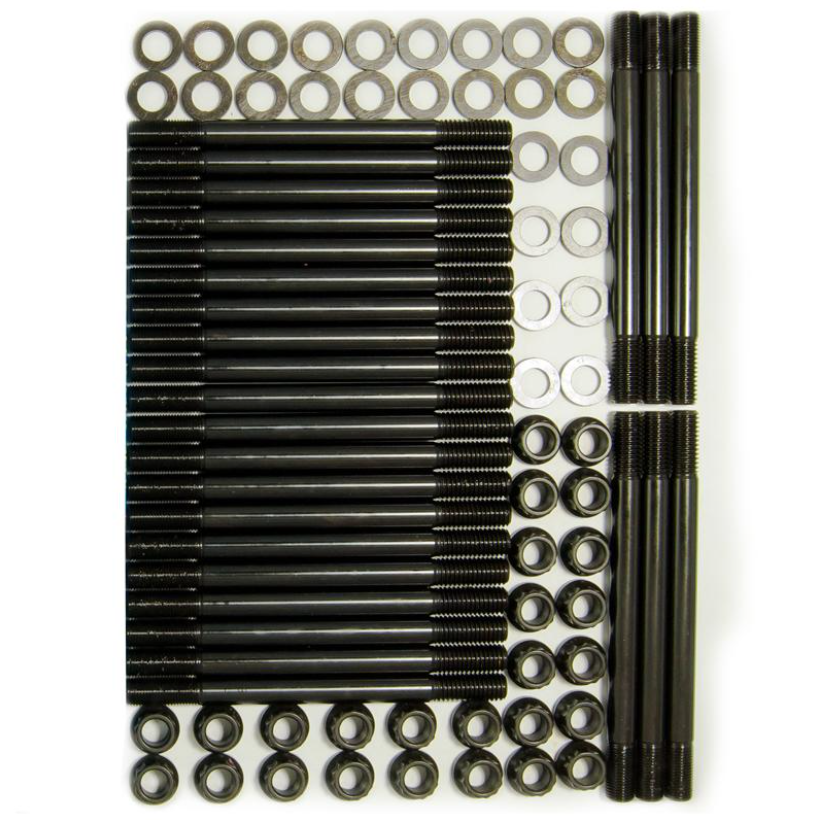

ARP 247-4202 DIESEL HEAD STUD KIT

ARP 247-4202 DIESEL HEAD STUD KIT

Couldn't load pickup availability

VEHICLE FITMENT:

1998.5-2023 DODGE RAM 5.9/6.7L DIESEL 24V

DESCRIPTION

The ARP 247-4202 Diesel Head Stud Kit let's you build your 1998.5-2023 Dodge Ram 5.9L/6.7L Diesel engine to last. It’s a proven fact that OEM head bolts are the weak link in a diesel engine; especially if the engine has been modified. That’s because most engines are typically assembled from the factory using Torque-To-Yield (TTY) bolts and preloaded to yield and beyond (typically 100-110%). Any increases in combustion pressure can lead to problems like blown head gaskets or catastrophic engine failure. And because TTY bolts are yielded by design, they should never be re-used.

ARP is the industry leader and builds heavy-duty head studs and fasteners for a wide variety of popular diesel applications. Using head studs instead of standard bolts provides your engine with the clamping force required to keep your cylinder head from lifting due to higher combustion pressures. For the 247-4202 Head Studs, ARP starts with a premium grade ARP2000 alloy that is rated far superior to aircraft quality alloy steels. ARP2000 is an alloy steel that can be safely heat treated to a higher level, producing a greater strength material than Chrome Moly 8740. While 8740 and ARP2000 share similar characteristics, ARP2000 is capable of achieving a higher clamp load at 220,000 psi.

Each stud is placed vertically into special racks and precisely heat-treated. This procedure ensures complete heat penetration, and the results are far superior to those lesser quality studs from other manufacturers who just dump pieces in a basket and hope for the best. The head studs next go through a centerless grinding process to ensure that they are perfectly concentric. As many as ten machining steps are required to achieve this level of accuracy. The thread rolling operation (to MIL-S-8879Aspecs) is also done after the heat-treatment, which gives them about 2000% (that’s twenty times) better fatigue strength than studs that are threaded prior to heat-treat. It costs a lot more to do it this way, because it’s tough on tooling, but the results are worth the extra eff ort. Fasteners are then shot-peened to remove any surface irregularities and improve overall external integrity. The final step is a metal finishing process that is also performed in-house at ARP with a black oxide coating applied for long lasting corrosion resistance.

It is for good reason that virtually every top professional engine builder relies on ARP head studs for their all-out competition powerplants. Simply stated, there’s not a better stud setup on the market today. This head stud kit is a direct-fit for 24-valve 5.9L and 6.7L diesel engines found in Dodge Ram 2500/3500 pickups.

FEATURES:

Proprietary ARP 2000 Material

Rated At 220,000 Psi Tensile Strength

Includes Chrome Moly Steel 12-Point Nuts

Black Oxide Coating For Added Corrosion Resistance

Centerless Ground To Ensure They Are Perfectly Concentric

Improved Clamping Force Prevents Cylinder Heads From Lifting

Broached Stud Ends Install & Make Cylinder Head Removal Easier

Heat-Treated Prior To Thread Rolling And Machining For Optimum Fatigue Strength

Shot-Peened To Remove Any Surface Irregularities And Improve Overall External Integrity

Hardened Parallel Ground Washers For An Even Load Distribution And Accurate Torque Readings

Comes With 0.5oz Of ARP Assembly Lubricant

Share